Date03.03.16

AuthorAli Reda, Eliane Ibrahim and Lamis Houssami

CompanyDar Al-Handasah

LocationAlgeria Middle East

Dealing with Swelling Pressure in a Tunnel in Algeria

Tunnel projects carry special challenges. One of these is the presence of swelling soils. This case study presents our team’s methodology for designing a tunnel’s final lining in swelling soils.

The swelling pressure and corresponding deformation are determined through the analytical method, while the soil-structure interaction is evaluated through the finite element method.

What are swelling soils?

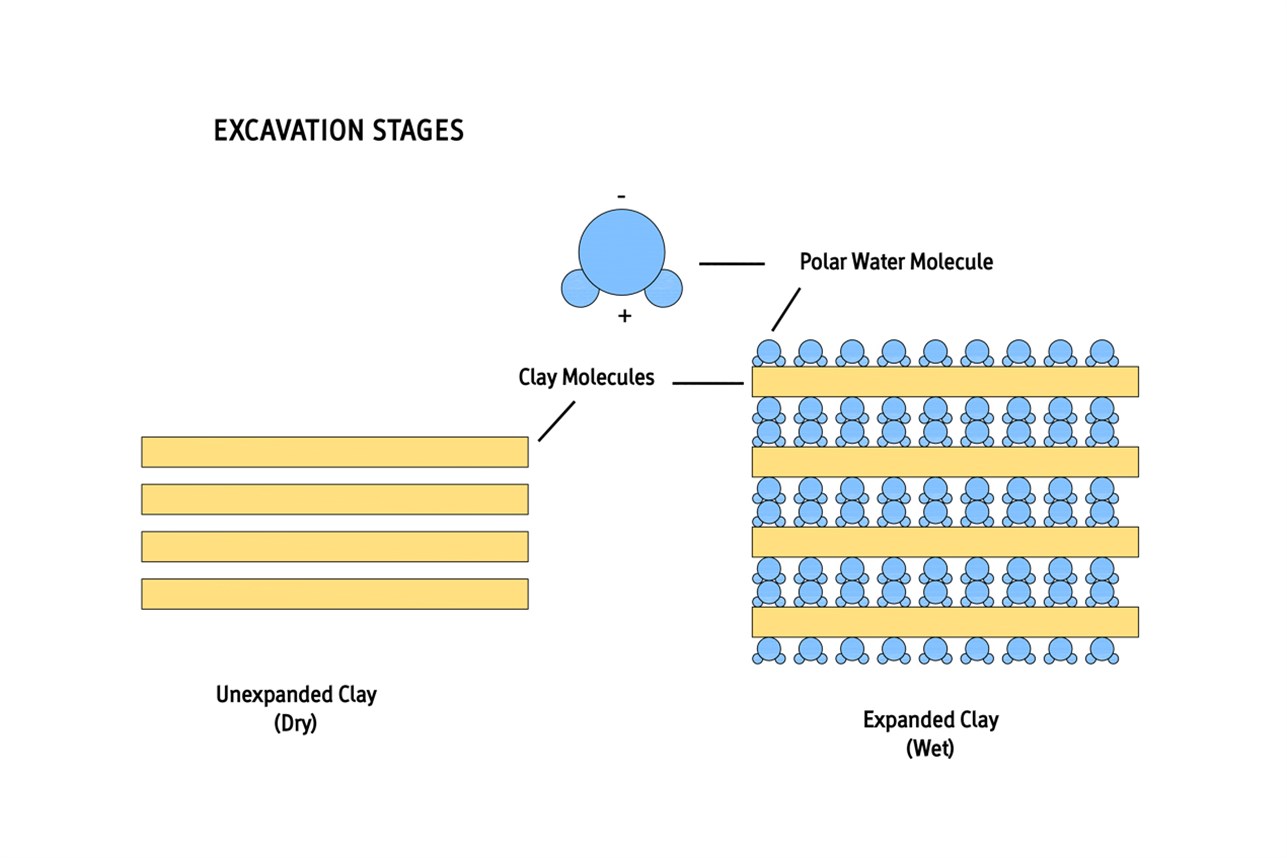

Swelling soils, also known as expansive soils, are soils that undergo a significant volume change due to a change in their water content. These soils contain smectite clay minerals, which at the microscopic level look like layered sheets. Because of the minerals’ moisture-retaining abilities, the more water these clays absorb and the less confined they are, the more they swell.

Why are expansive soils problematic?

In tunnels, swelling behavior is defined as a volume increase leading to an inward movement of the tunnel’s

perimeter. It starts at the excavation stage, carries on during execution and may continue long after final lining

installation. During excavation, the intrusion of water in the surrounding unsaturated material causes a change in the volume of the existing expansive soil. The soil at that point is under unconstrained conditions. When the tunnel lining is constructed, expansion is restrained. As a result, the swelling imposes significant forces and deformations on the lining.

Djebel El Kantour tunnel

Our case study is a tunnel project in Algeria, part of the Section 4 of the East-West Highway project, Lot East. The tunnel crosses Djebel El Kantour northeast of Constantine City. The area is characterized by Lower Cretaceous age formations consisting of heavily folded and fractured blocks of marl and limestone, and covered by Quaternary deposits such as clay, silts and conglomerates. What is interesting about this project is that the tunnel had to be excavated in weathered, partially saturated marl and marly clay layers. These layers have a moderate to high swelling potential.

The expansive clay’s effect on the tunnel lining is set to be a major challenge. The design method that is presented in full below is adopted to determine the needed tunnel lining support at every construction stage.

Determining swelling pressure

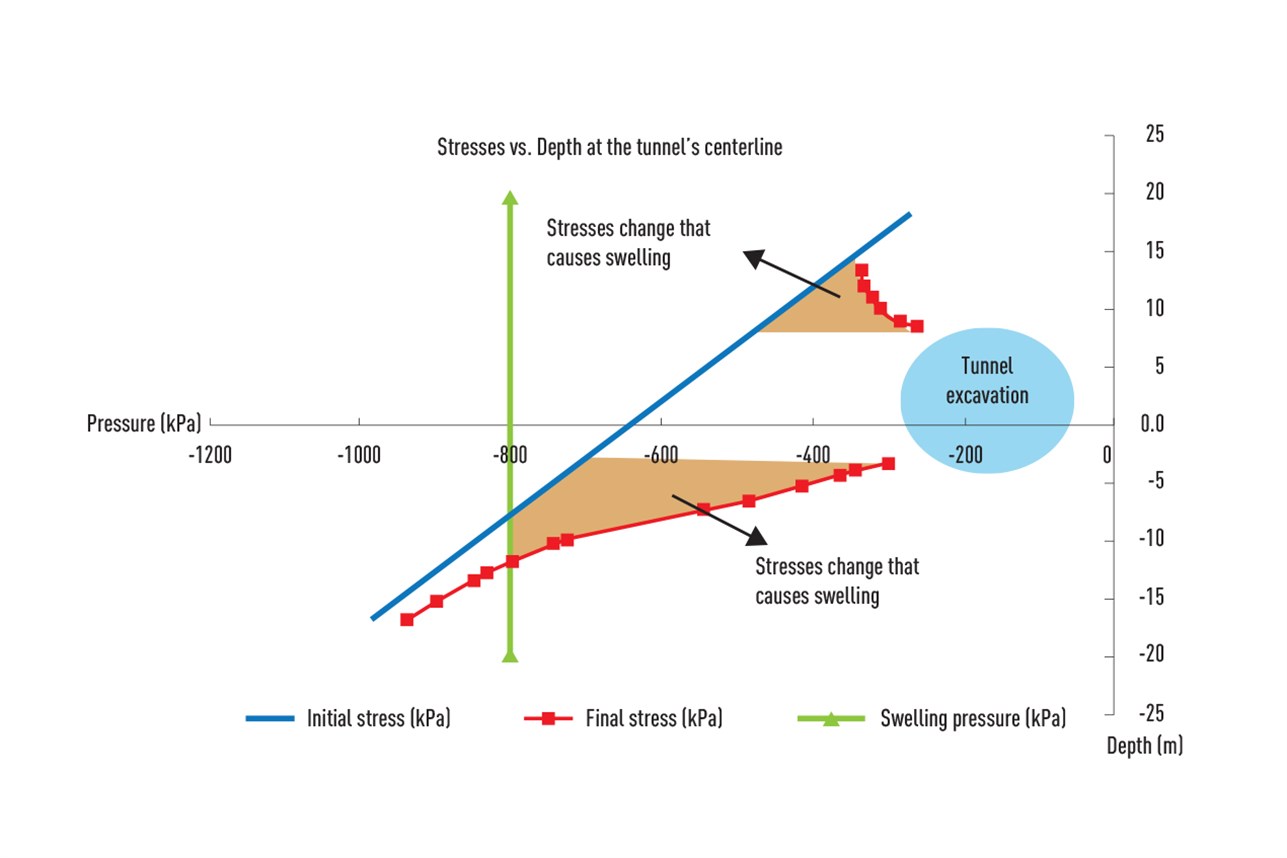

Our first task was determining the swelling pressure. For that, we conducted a series of swelling oedometric tests that gave us the one-dimensional swelling deformation parameter for the marly clay. Swelling pressure was found to be 800 kPa with a 3% strain at free swell. We then obtained the 3D stresses and strains using Kiehl’s 1990 equation.

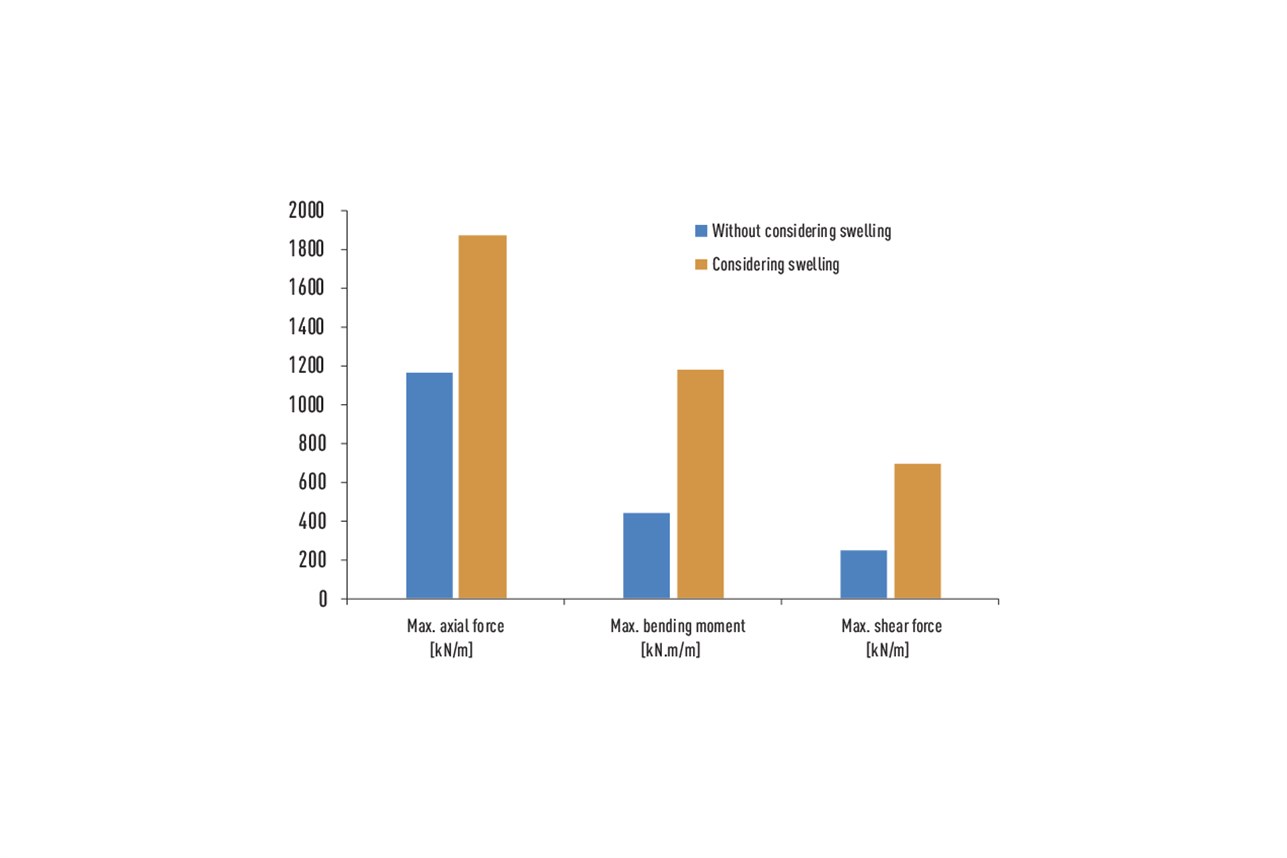

Calculating swelling effect on tunnel lining

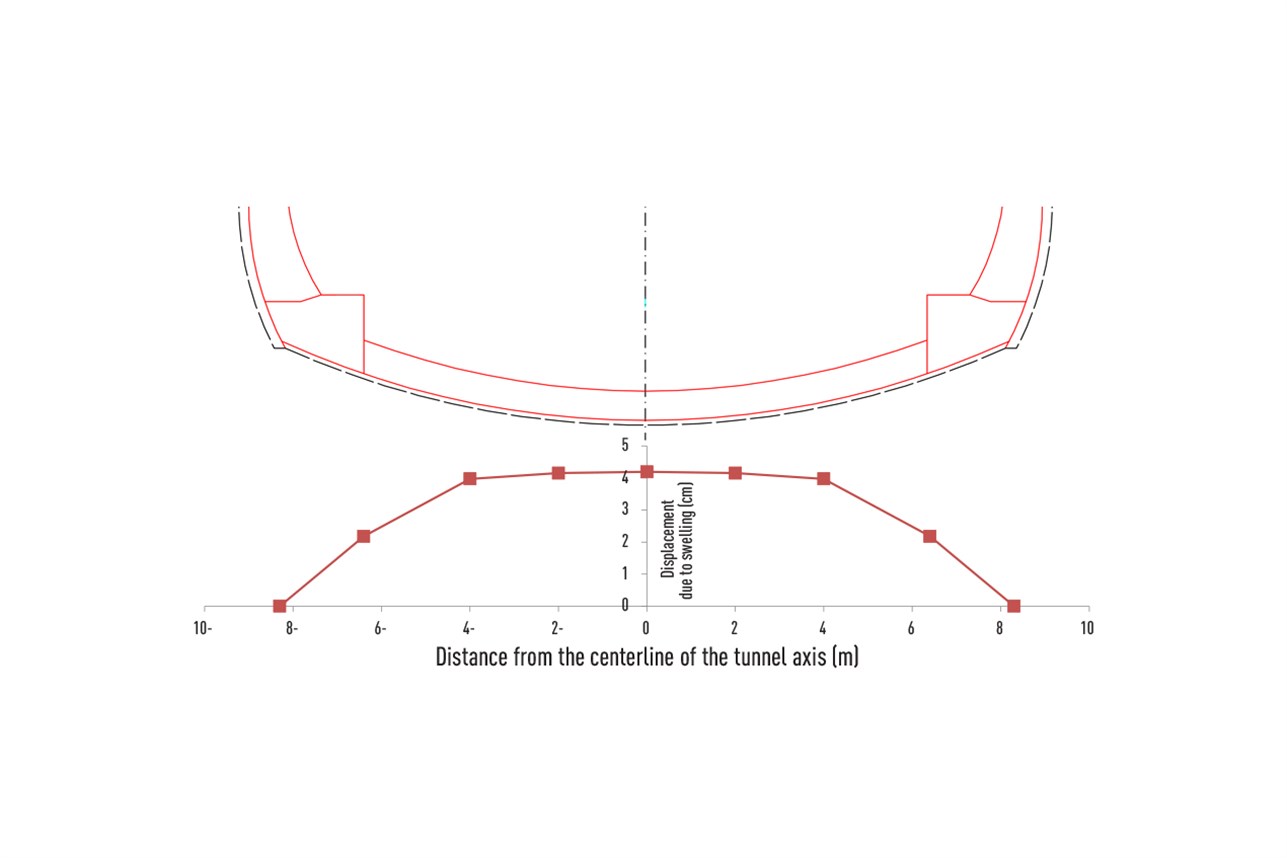

We modelled the tunnel construction using a plane strain finite element model and considering the excavation stages, the installation of the temporary support, the placement of the final lining, as well as the soil-structure interaction. In this model, we applied prescribed displacements at the bottom of the invert to represent the swelling effect. Accordingly, the resulting forces and bending moments inside the lining at the final stage of the construction were computed.

- The mean initial stress and the stress decrease further to the tunnel excavation are plotted versus depth.

- The depth of influence of swelling below the invert is determined from the area between the initial stress and the final stress, limited by the swelling pressure (Wittke-Gatterman, 1998).

- The swelling strain is then obtained by integrating the strain with depth as suggested by Kiehl (1990).

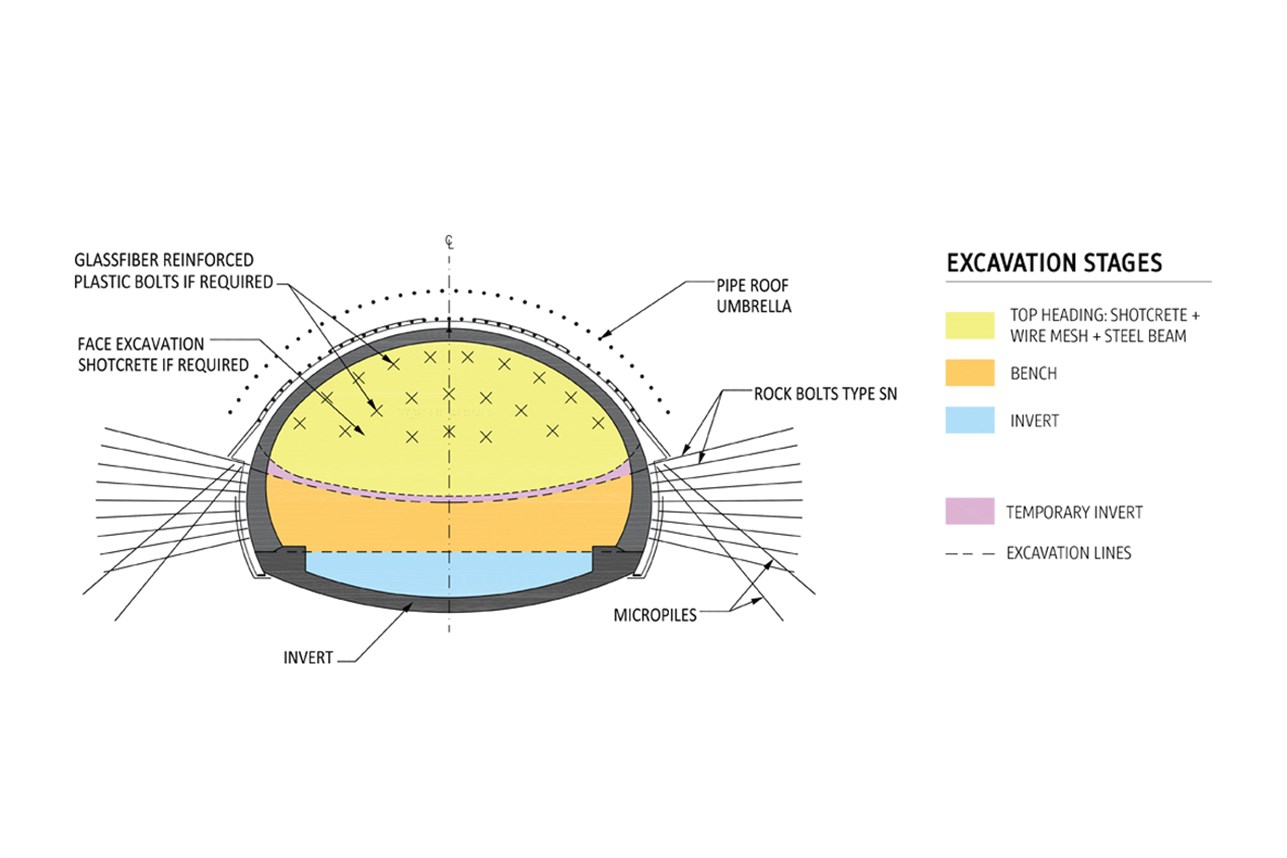

Temporary support and final lining

The temporary support of the tunnel consisted of a combination of shotcrete, wire mesh, steel arches, and rock bolts.

The tunnel invert was immediately placed after the last stage of excavation, so it could inhibit the deformations

due to swelling.

The reinforcements were assembled outside the tunnel in order to minimize the time between both activities.

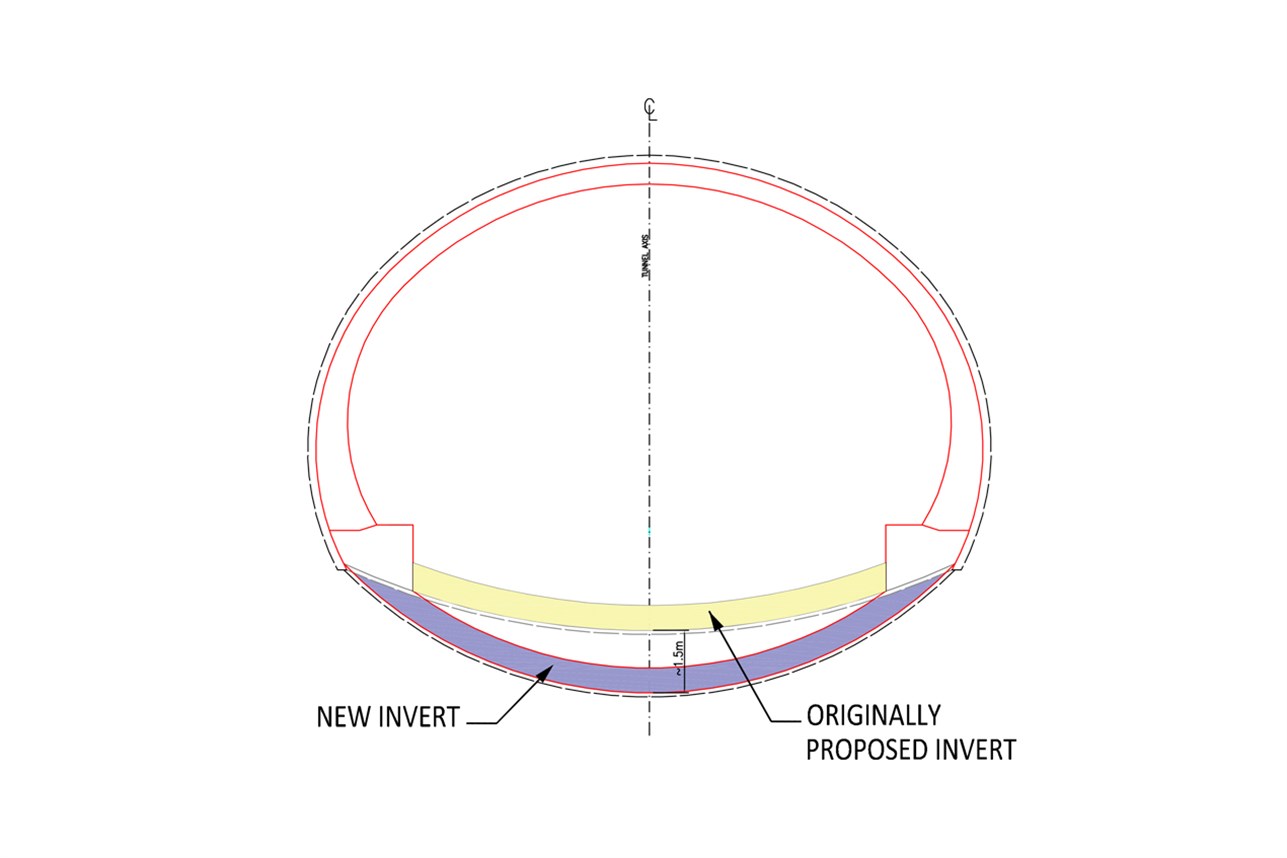

However, the reinforcement cages turned out to be very heavy to carry and move easily. Therefore, it was

necessary to reduce the reinforcement and accelerate the task on site. For this, the curvature of the invert was

increased to force the lining to take the straining actions by axial force and hence decrease the moment – and eventually the reinforcement.

The difference in swelling levels along the tunnel results in differential settlements, causing cracks in the final lining after a certain period of time.

For this reason, there was a need for longitudinal reinforcement along tunnel axis, especially in transition zones between different soil types with different swelling potentials. Depending on the stress level and the cover above the tunnel, the swelling degree was measured.

During advancement of the excavation, the initial design was consistently checked against the actually encountered geologic conditions and the deformation monitoring readings.

Determining the impact of the swelling pressure on the tunnel final lining required adopting analytical and

finite elements methods. We dealt with the swelling effect on the final lining through increasing the density of the reinforcement within the invert. However, this solution was dropped due to logistical constraints and hence the invert curvature was increased as a substitute solution.